Hey there! Well, we are going to discuss Wooden Office Organizers that were made in bulk one day as a group. We call this "batch production". Often when we make a large amount of same product we need to consider few important points so that everything goes smoothly. Here are a few things to consider when you are preparing batches of office organizers made of wooden craft.

Some of the important points to remember when you want to optimize the batch production of wooden office organizers:

Here version three as we work through how best to batch out wooden office organizers. Design is another aspect to consider when buying an organizer. We also want to ensure the design is easy to use and produce. It will also be a time saver for us as well as ensuring all the organizers have matching uniforms.

Other integrations too is the tools and equipment we use. The Before and After photo shows what a difference they make But you definitely need to have the right tools and machines that can keep up with making hundreds of organizers at a time. This will enable us to perform more quickly and have a greater output.

Authorizing wooden desk organizers manufacturing:

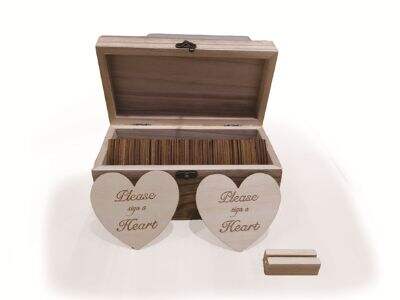

Streamlining our production processes simply means ensuring that things run smoothly and professionally. For example, we can ensure that our work area is designed to easily transition from one task into the next. This wooden container will save us time and will prevent any confusion.

Creating a plan, setting up a schedule and following it can help streamline our content production in the same way that an editorial calendar helps us organize and coordinate all your marketing efforts. This helps ensure each part of the production process is completed on time and in the correct order.

Office organizers: batch production and quality control steps (how to produce 500 in a week):

Quality control means that our wood office organizers are built to the highest standards. We need to inspect every organizer as its being made in a batch production so that we stop any mistake at the process.

Assuring quality of the finished bogus thing is one route: A qualified saying learned observer can review all things as they are delivered. It allows them to inspect for defects or errors and verifies that everything is in order.

Batch production efficient material selection& sourcing strategies:

Best Materials for Making Office Organiser in Wood in Bulk Top grades of the strongest, most durable woods available. This wooden display case will make sure your organiser last ages and stands up to everyday wear and tear.

We need to consider our source for materials as well. Building Relationships with Suppliers to Ensure a Steady Wood Supply. Sources all of our wood from actual suppliers in the insatiable mission to keep everything running.

Applying lean manufacturing principles wood office organizers:

Our more efficient production processes making us have to be leaner (Lean manufacturing, for those who know)? This can be achieved by using just-in-time production producing only when someone wants an organizer. This may help to lower work in process inventory and save costs.

Continuous Improvement

A further lean manufacturing guideline is continuous improvement. We will be able to work faster and smarter by always looking for ways to improve our production procedures.

Summary:

So to sum up building office organizers in bulk is achieved after thinking about multiple factors. Through design, tools, production process set-up, quality control, material selection and by embracing things like lean manufacturing principles, we can really get our production optimised and make some great organisers quickly. Thank you for reading, and remember, at Best Goal we aim high in everything we do.

Table of Contents

- Some of the important points to remember when you want to optimize the batch production of wooden office organizers:

- Authorizing wooden desk organizers manufacturing:

- Office organizers: batch production and quality control steps (how to produce 500 in a week):

- Batch production efficient material selection& sourcing strategies:

- Applying lean manufacturing principles wood office organizers:

- Continuous Improvement

- Summary:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

LA

LA

KK

KK

SU

SU

UZ

UZ

LB

LB